În economia actuală, orientată spre precizie, în special în sectorul manufacturier, timpul este esențial. Importanța menținerii calității produselor, dar și a creșterii productivității, este de o importanță majoră. Mașinile de sigilat complet automatizate reprezintă una dintre inovațiile tehnologice capabile să asigure atingerea ambelor obiective. Scopul acestui conținut este de a explica rolul mașinilor de sigilat complet automatizate în procesele moderne de ambalare.

Primul aspect care poate fi menționat despre mașinile de sigilat complet automatizate este capacitatea lor de a crește capacitatea de producție. Mașinile de sigilat complet automatizate cresc producția la un nivel foarte ridicat, menținând în același timp calitatea, iar designurile modulare ale mașinilor automate de sigilat garantează un output echilibrat la toate etapele. Acest lucru va elimina complet nevoia de oprire extinsă, caracteristică de obicei proceselor manuale de sigilare. În plus, respectarea obligațiilor față de partenerii de afaceri va deveni mult mai ușoară.

În comparație cu tehnici de sigilare manuale, mașinile automate oferă o precizie fără seamăn, alături de consistență. Unul dintre cele mai atrăgătoare avantaje ale mașinilor de sigilat este precizia lor semnificativ îmbunătățită. Mașinile de sigilat complet automate pot realiza sigilări cu precizie multi-strat, în timp ce se adaptează la cerințele dinamice de sigilare ale fiecărei serii de producție. Acest aspect este deosebit de important în industria alimentară și farmaceutică, pentru a garanta siguranța și integritatea produselor. O reputație îmbunătățită poate fi, de asemenea, obținută prin reducerea numărului de retrageri de produse, ca urmare a scăderii erorilor umane, care atenuează riscurile.

În plus, mașinile automate de sigilare pot ajuta la reducerea costurilor în timp. Deși mașinile complet automate au un cost de achiziție mai mare decât sigilatoarele manuale, pe termen lung vor fi necesari mai puțini angajați, iar productivitatea va fi mai mare, rezultând un randament al investiției. În plus, mașinile de sigilat complet automate sunt mult mai eficiente din punct de vedere al costurilor, deoarece sunt concepute pentru a reduce risipa excesivă de materiale.

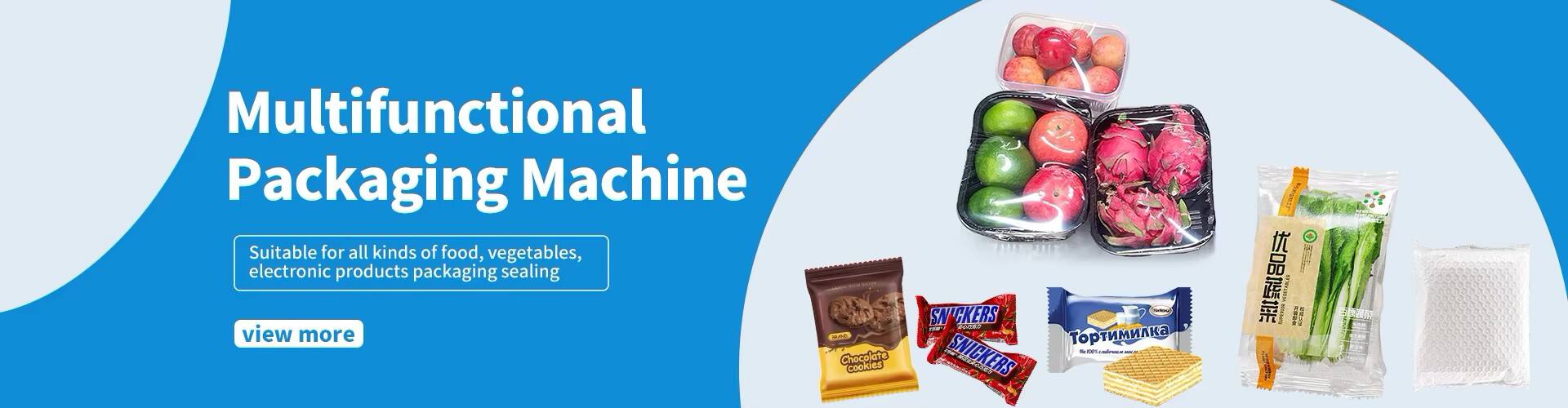

Mâșinile de sigilat complet automatice își pot schimba și tipurile de ambalaje sigilate. Acestea sunt capabile să deservească o varietate de pungi și sticle utilizate în numeroase industrii. Această flexibilitate în deservire permite companiilor care doresc să se diversifice și să crească să nu cheltuiască mulți bani pentru achiziționarea mai multor mașini de sigilat.

În final, funcțiile avansate ale mașinilor de sigilat complet automatice îmbunătățesc funcționalitatea acestora. Setările programabile, controalele cu ecran tactil și sistemele de monitorizare în timp real oferă toate operatorilor abilitatea de a controla mai bine procesul de sigilare. Un control mai bun al mașinilor ajută, de asemenea, companiile să colecteze informații utile și să își îmbunătățească operațiunile, iar automatizarea ecranelor tactile simplifică operațiunile.

Pe scurt, mașinile de sigilat complet automatizate sunt esențiale în procesele moderne de producție și ambalare. Investițiile în tehnologii automate versatile, care necesită o supraveghere minimă din partea operatorilor umani, devin populare datorită capacității lor de a spori productivitatea, de a asigura o producție uniformă și de a reduce cheltuielile operaționale. Dacă luăm în considerare actualele tendințe tehnologice, utilizarea unor tehnologii avansate de sigilare automată va deveni în curând normă în industria producției și a ambalării.